Improper placement of materials in a wall can lead to condensation on colder surfaces water damaged insulation and building materials as well as fungal growth.

Cellulose fiber based fungal and water resistant insulation materials.

The cellulose fiber foams have a low density 33 66 kg m3 and can inhibit microbial growth.

It is made from paper that has a minimum of 85 recycled content such as newspaper.

Cellulose fiber based thermal insulation materials with fungal resistance improved water resistance and reaction to fire properties zheng chao kth school of chemical science and engineering che fibre and polymer technology wood chemistry and pulp technology.

Fiberglass fibers may become airborne which can be considered a pollutant.

Water stable cellulose fiber foams have been produced in a simple one batch foam forming process with drying under ambient conditions.

Two highly valuable features for insulating packaging materials especially in combination with stability in water.

It does not pollute the air during manufacture or use as much energy to produce as fiberglass.

In the present study cellulose fiber based insulation foams made of bleached chemi thermo mechanical pulp ctmp have been investigated.

The thesis demonstrates that it is possible to produce cellulose fiber based insulation materials with improved properties in terms of fungal improved water resistance and reaction to fire properties.

The cellulose fiber foams have a low density 33 66 kg m3 and can inhibit microbial growth.

Kth royal institute of technology 2017.

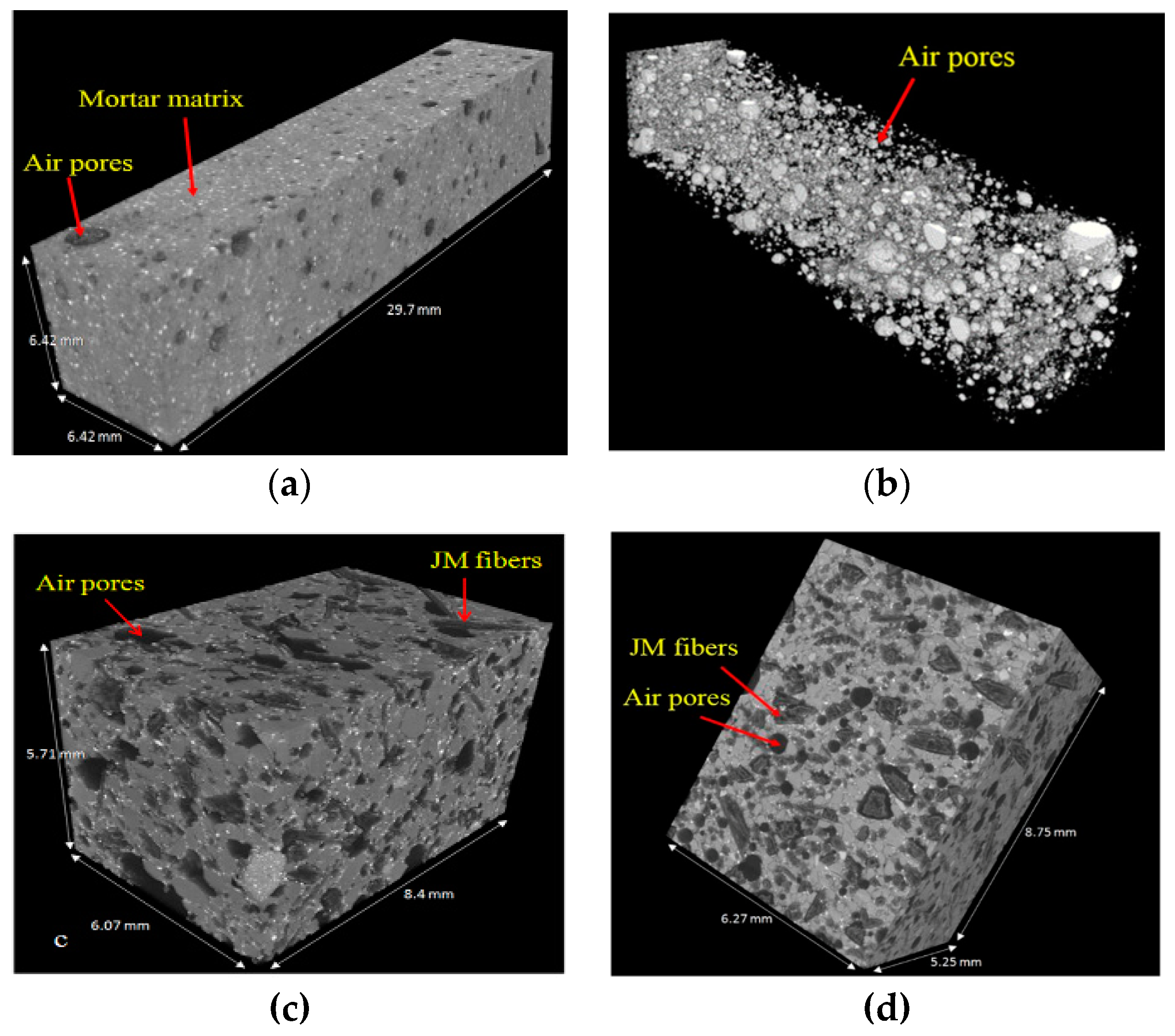

The surface morphology of the foams and the distribution of the deposited particles from the extractives were observed by scanning electron microscopy sem.

Materials with lower.

Cellulose fiber based fungal and water resistant insulation materials.

Cellulose insulation is considered a greener material than fiberglass.

Often referred to as breathability vapor permeability describes a material s ability to allow water vapor to pass through it measured in units called perms.

Water stable cellulose fiber foams have been produced in a simple one batch foam forming process with drying under ambient conditions.

Cellulose fiber based insulation foams made of bleached chemi thermo mechanical pulp ctmp have been investigated.

In the present study cellulose fiber based insulation foams made of bleached chemi thermo mechanical pulp ctmp have been investigated.

To improve water resistance the foams were impregnated with hydrophobic extractives from the outer bark of birch betula verrucosa and dried.

To improve water resistance the foams were impregnated.